[ITEM]

[/ITEM]

[/ITEM]

28.01.2019

43

Corrective and Preventive Action Management are two different management systems within ISO 9001 requirements. Talking with other professionals, I find that there is confusion between these 3 items, corrective action, preventive action and preventive maintenance.

ISO 9001 - 8.5.3 Preventive action - written in plain English with practical guidance and interpretation. Applying a proven corrective action to other areas of the business; Being aware of changes. To understand what an auditor will look for, see the Auditing Preventive Action paper on ISO 9000 Auditing Practices Groups' website. A common question we get asked during our training courses is what is the difference between correction, corrective action and preventive action? Skip to content. Search for: delivering expert training since 1962 Menu. ISO 9001 Quality. ISO 9001 Foundation. Is what is the difference between correction, corrective action.

Corrective action treats a nonconformity or problem that has already occurred. The problem exists. The nonconformity lives and needs to be addressed.

Preventive maintenance focuses on the care of machines. It is a system that protects machines from breaking down. ISO 9001 auditors do not look at preventive maintenance as preventive action. Preventive maintenance is important for the infrastructure (resource management) section of the ISO 9001 standard. Preventive action determines and eliminates potential causes of non conformities.

This means the non conformity has not yet happen. If you act to prevent a problem from occurring then this is a preventive action.

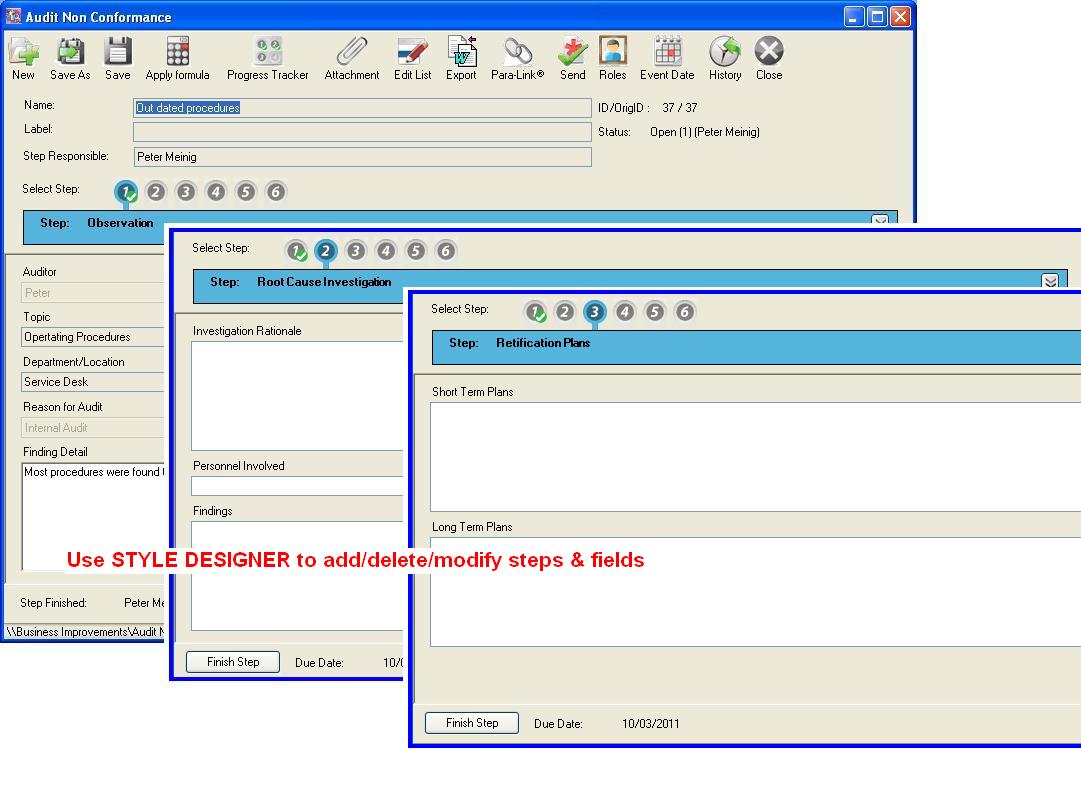

The ISO 9001 standard requires you to take preventive action to eliminate potential nonconformities. With 8D, 9D, 5Y and 4M report generator. Corrective action software for managing, measuring, and reporting. How to install usb wifi adapter on kali linux wallpaper white background images. Corrective and Preventive Action Management Documentation A documented procedure is required for ISO 9001 certification.

Within the procedure explain how your company • defines the determination of potential problems • defines the possible causes of problems • determines the action needed to address the potential problem • implements actions necessary to prevent the cause of the problems • records the preventive action taken. • reviews the preventive action taken.

You must have a documented system that covers CAPA management systems. The same document could be used for both. Be sure there are separate sections for corrective action and preventive action. With 8D, 9D, 5Y and 4M report generator. Corrective action software for managing, measuring, and reporting. Preventive Action Examples • Revising a procedure to reduce the variation between operators is a preventive action.

- Author: admin

- Category: Category

Search

Most Viewed Pages

- Samehadaku Bleach

- Milo Manara Borgia 3 Pdf Files

- Dsj 3 Klucz Zawodnicy Mma

- Ebook Shalat Idul Adha

- Epson L382 Resetter Free Download Rar

- Suikoden II Mb Ringan Psx

- Foto Payudara Kencang Wanita

- Layarkaca21 Drama Taiwan

- Comprehensive Meta Analysis Keygen Music

- Easeus Data Recovery Wizard Serial Number Mac Mini

- Cutepdf Install Printer Failed Error 1798 Consultants

- Giddha Bolyian Mast Ali And Satwant Kaur Darra Mp3 Song On Pendu Jatt

- Google Buku Manajemen Pemasaran Philip Kotler Jilid 1

- Pdf Buku Philip Kotler Edisi 13

Corrective and Preventive Action Management are two different management systems within ISO 9001 requirements. Talking with other professionals, I find that there is confusion between these 3 items, corrective action, preventive action and preventive maintenance.

ISO 9001 - 8.5.3 Preventive action - written in plain English with practical guidance and interpretation. Applying a proven corrective action to other areas of the business; Being aware of changes. To understand what an auditor will look for, see the Auditing Preventive Action paper on ISO 9000 Auditing Practices Groups' website. A common question we get asked during our training courses is what is the difference between correction, corrective action and preventive action? Skip to content. Search for: delivering expert training since 1962 Menu. ISO 9001 Quality. ISO 9001 Foundation. Is what is the difference between correction, corrective action.

Corrective action treats a nonconformity or problem that has already occurred. The problem exists. The nonconformity lives and needs to be addressed.

Preventive maintenance focuses on the care of machines. It is a system that protects machines from breaking down. ISO 9001 auditors do not look at preventive maintenance as preventive action. Preventive maintenance is important for the infrastructure (resource management) section of the ISO 9001 standard. Preventive action determines and eliminates potential causes of non conformities.

This means the non conformity has not yet happen. If you act to prevent a problem from occurring then this is a preventive action.

The ISO 9001 standard requires you to take preventive action to eliminate potential nonconformities. With 8D, 9D, 5Y and 4M report generator. Corrective action software for managing, measuring, and reporting. How to install usb wifi adapter on kali linux wallpaper white background images. Corrective and Preventive Action Management Documentation A documented procedure is required for ISO 9001 certification.

Within the procedure explain how your company • defines the determination of potential problems • defines the possible causes of problems • determines the action needed to address the potential problem • implements actions necessary to prevent the cause of the problems • records the preventive action taken. • reviews the preventive action taken.

You must have a documented system that covers CAPA management systems. The same document could be used for both. Be sure there are separate sections for corrective action and preventive action. With 8D, 9D, 5Y and 4M report generator. Corrective action software for managing, measuring, and reporting. Preventive Action Examples • Revising a procedure to reduce the variation between operators is a preventive action.

Search

Most Viewed Pages

- Samehadaku Bleach

- Milo Manara Borgia 3 Pdf Files

- Dsj 3 Klucz Zawodnicy Mma

- Ebook Shalat Idul Adha

- Epson L382 Resetter Free Download Rar

- Suikoden II Mb Ringan Psx

- Foto Payudara Kencang Wanita

- Layarkaca21 Drama Taiwan

- Comprehensive Meta Analysis Keygen Music

- Easeus Data Recovery Wizard Serial Number Mac Mini

- Cutepdf Install Printer Failed Error 1798 Consultants

- Giddha Bolyian Mast Ali And Satwant Kaur Darra Mp3 Song On Pendu Jatt

- Google Buku Manajemen Pemasaran Philip Kotler Jilid 1

- Pdf Buku Philip Kotler Edisi 13